FlexMax CNC

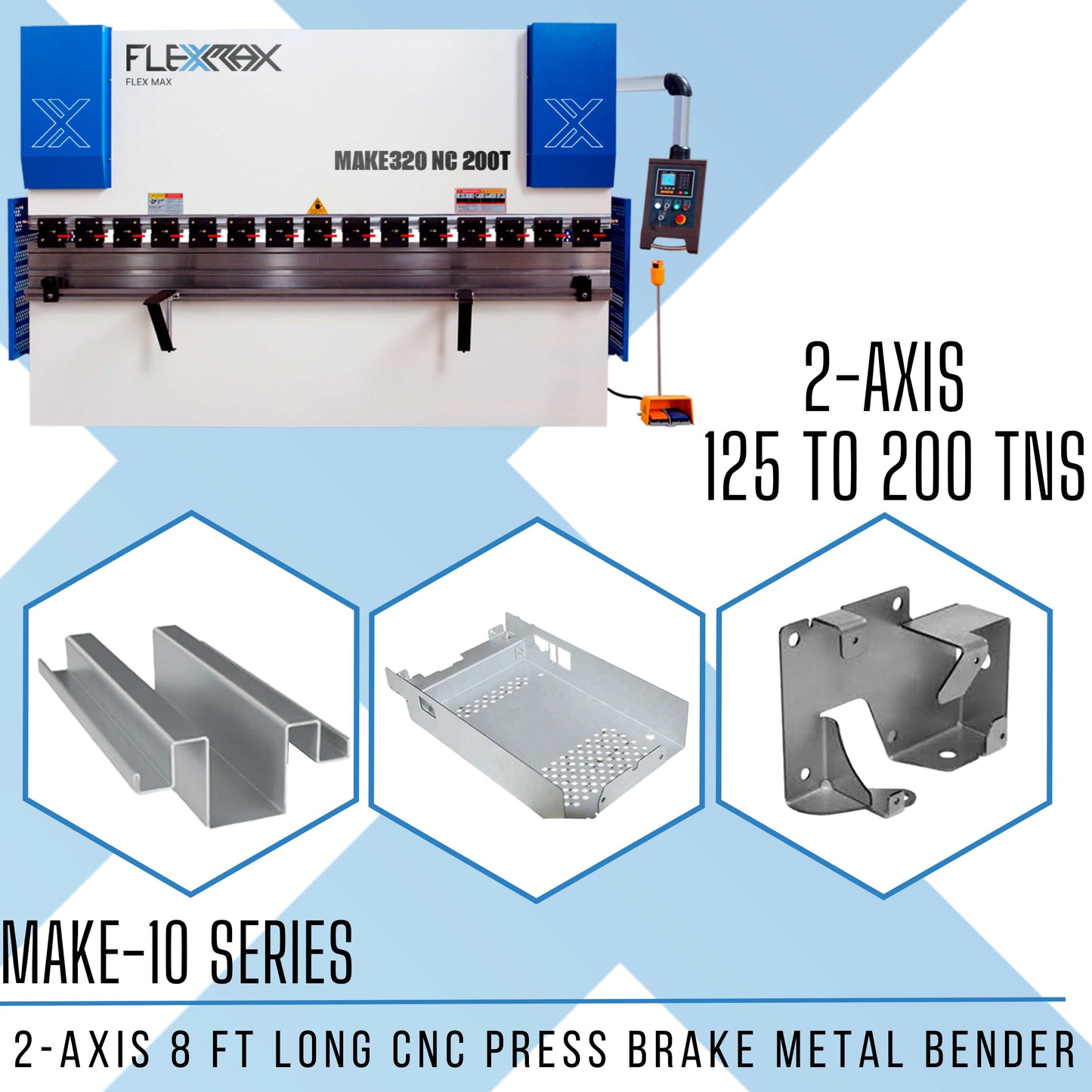

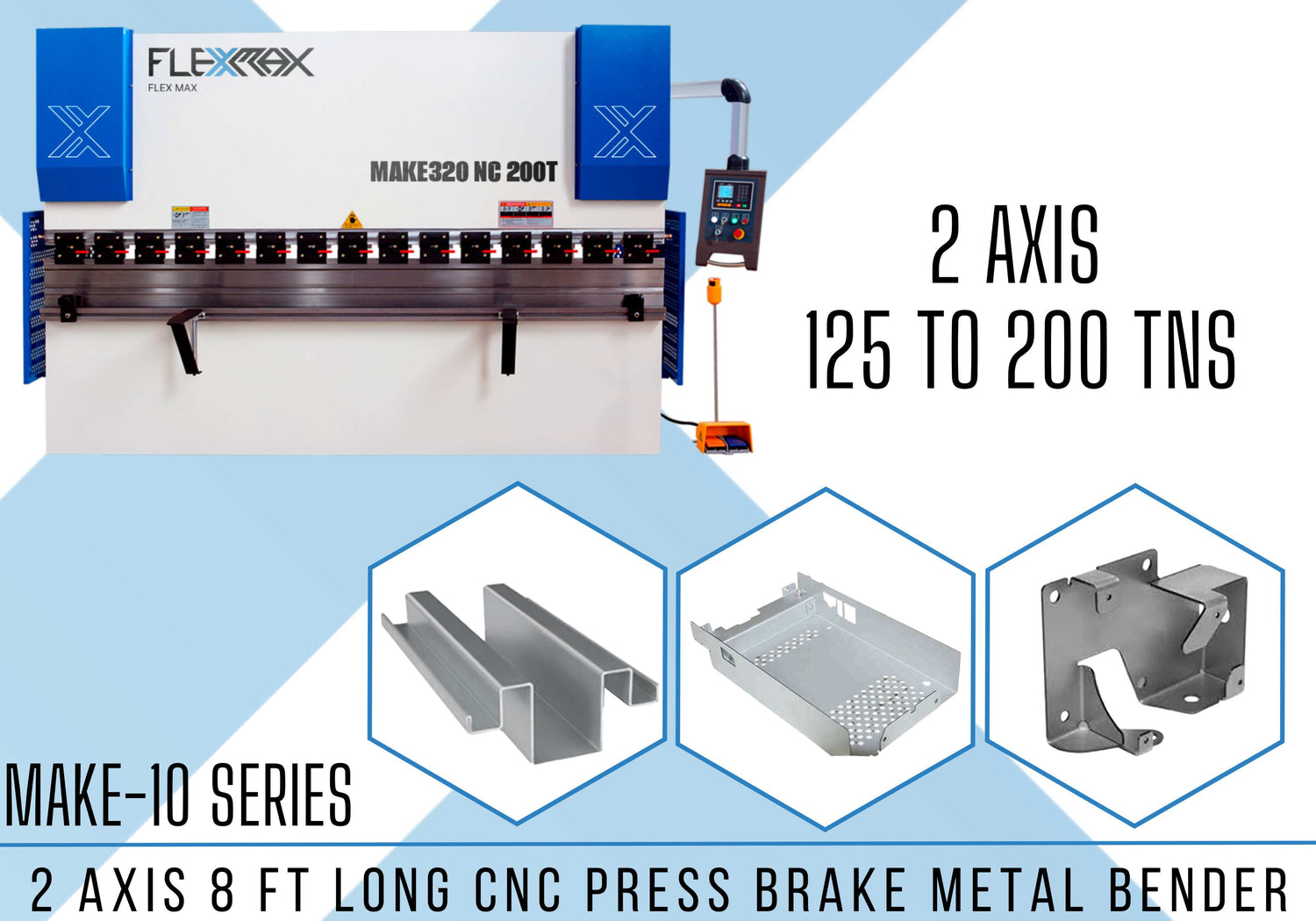

125tns to 200tns, 10ft long FlexMax CNC 3+1 AXIS MAKE-10 Series Hydraulic Press Brake Metal Bender

125tns to 200tns, 10ft long FlexMax CNC 3+1 AXIS MAKE-10 Series Hydraulic Press Brake Metal Bender

SALE METHOD: FROM THE FACTORY TO YOUR FACTORY WITH LOCAL TRAINING AND SUPPORT

Our MAKE-10 Series 10 feet long press brake metal bender includes:

✔ FREE Shipping* (Tow truck crane is required to unload)

✔ 3-DAY Full Pack On-site Installation and training

✔ 125 and 200 tons force pressure

✔ 10 feet long bending area (Available 5.2 ft and 8.2ft)

✔ 125 tons bending capacity: Mild steel from 3/16 (10ft piece long) to 1/2" (5ft piece long). Stainless steel bends at 30% less capacity on average, depending on the alloy

✔ 200 tons bending capacity: Mild steel from 1/4" (10ft piece long) to 5/8" (7ft piece long). (Stainless steel bends at 30% less capacity on average, depending on the alloy)

✔ TP10S Full color touch screen programmable control system

✔ SIEMENS Powerful Motor

✔ 3+1 Axis (X/Y/R + Crowing) high precision movement

✔ Heavy-duty frame designed to reduce vibrations

✔ Rexroth by Bosch hydraulic valve to control the oil fluid perfectly

✔ First or Haldex hydraulic pump

✔ Gooseneck tooling Multi-Vee Die included

✔ The foot pedal grants complete overbending functions

✔ Schneider electric components

✔ Bend stainless steel, mild steel, aluminum, and brass

Couldn't load pickup availability

Share

INTRODUCTION

Our MAKE-10 Series, with a 10-foot bending capacity, offers a hydraulic system with compact and simplified electricity. It is equipped with the E21NC control system and Rexroth hydraulic valve, which gives your project high-precision performance.

TOP COMPONENTS

Our MAKE Series features top-of-the-line components from the world's leading brands to ensure exceptional quality tailored to each model.

TP10S CONTROL SYSTEM

Our touch screen is entirely colored and enables precise programming of bending sequences along with the adjustment of various compressions in the panel.

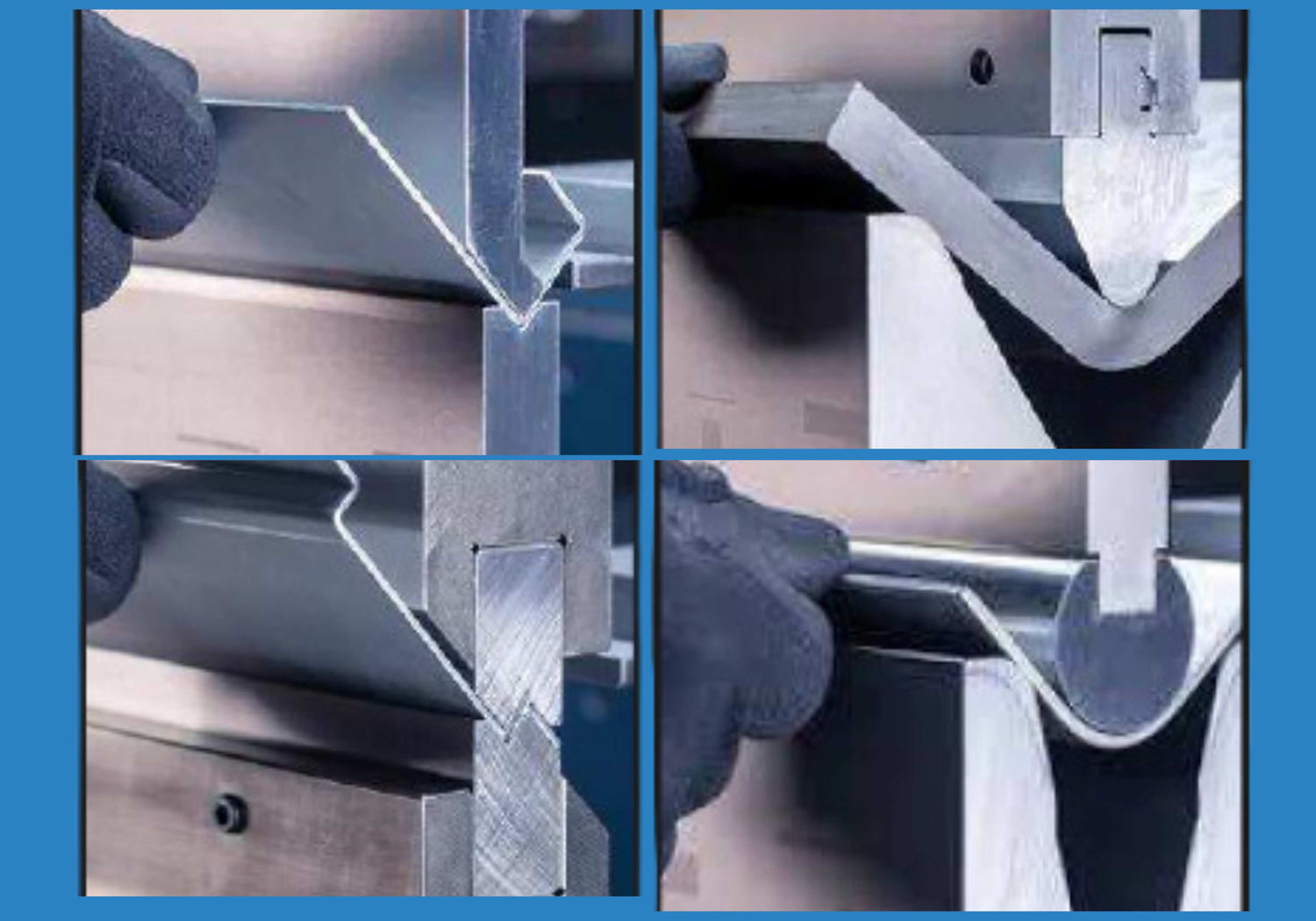

BENDING OPTIONS

Experience support for standard tools available on the market, ideal for all your bending needs.

STANDARD GOOSENECK + MULTI-V

The package includes the multipurpose gooseneck punch, and the versatile MULTI-V die tool.

FOOT SWITCH

Experience the flexibility and durability of our foot switch, designed with its emergency button to ensure safe and secure operation. Achieve precision with ease.

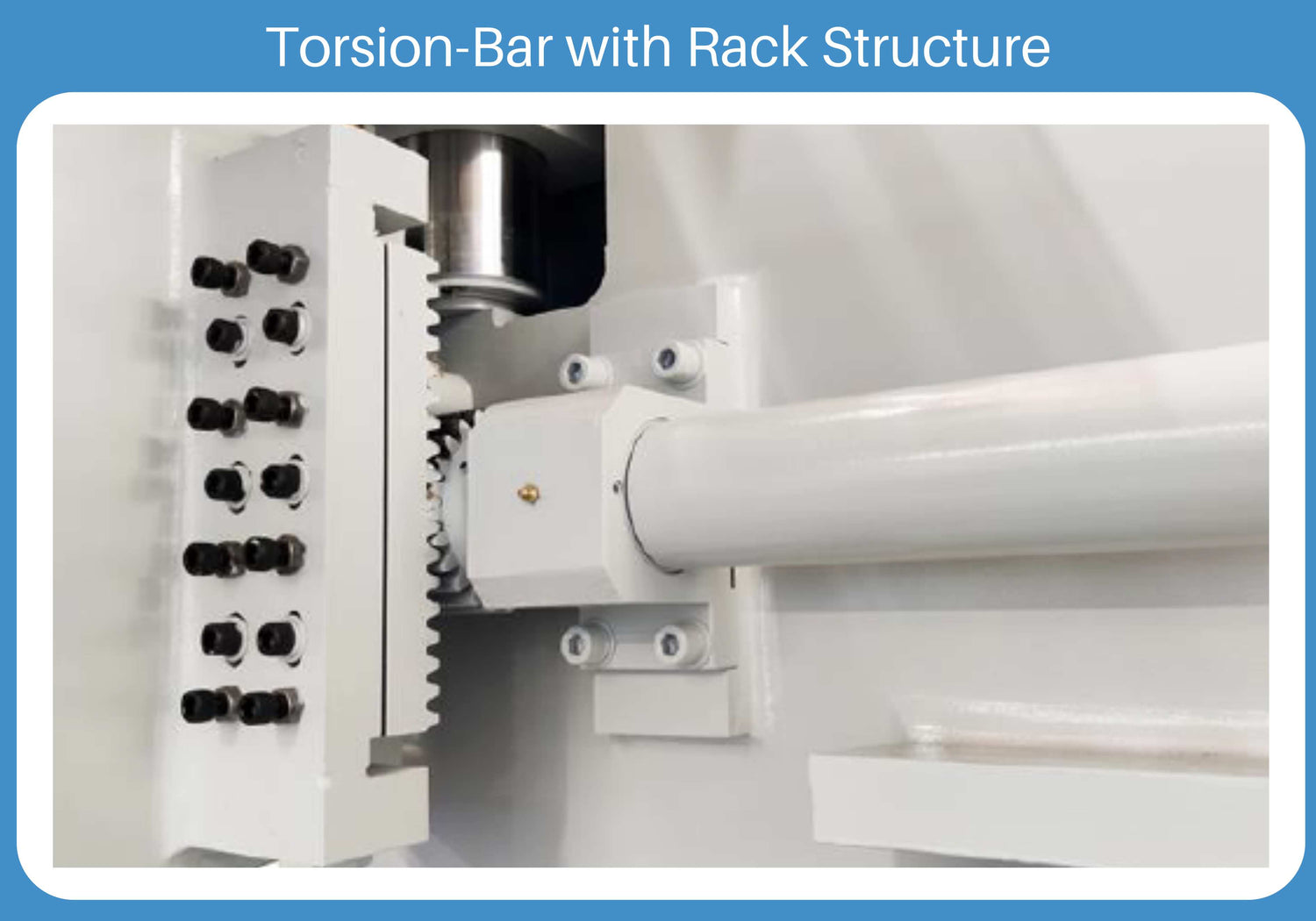

TORSION BAR

Achieve less friction, longer lifespan, less resistance, fast-moving speed, multi-point control, easy gap adjustment, and less maintenance.

ADJUSTABLE R AXIS

The r-axis allows you to control the vertical movement of the back gauge with precision. The sturdy and smooth material ensures high precision, making your work easier.

SAFETY FEATURES

Ensure worker safety with our advanced MSD device and light curtain, providing laser protection against rapid slider movement. Protect against potential dangers and keep workers safe from harm.

FACTORY TO FACTORY

We ship the machine directly from the factory to your location anywhere in the USA. Once it arrives, an engineer will install it and train you to use it with your materials and projects. ALL-INCLUSIVE!

125tns to 200tns, 10ft long FlexMax CNC 3+1 AXIS MAKE-10 Series Hydraulic Press Brake Metal Bender

Collapsible content

TECHNICAL SPECIFICATIONS

Models: MAKE-10-NC125T and MAKE-10-NC200T.

Controller: E21 NC Computer Controller with 40 programs control system.

Bending force: 125 tons (MAKE-10-NC125T) and 200 tons (MAKE-10-NC200T)

Bending area: 10 ft ( 120" / 3050mm)

AXIS: 2 Axis (X/R)

Punches: European type (facilitates quick change)

Cylinders: Hydraulic machined from solid with quality sealing

Distance between columns: 2600 mm

Throat depth: 320 mm

RAM stroke: 120mm (125T) / 200mm (200T)

Maximum opening height: 370 mm (125T) / 460mm (200T)

RAM speed reduction: 85 mm/sec

RAM Back/Work speed: 80mm/sec / 5~12mm/sec

Linearity of bent parts: 0.5 mm

Front Sliding Arms: 2 (Included)

Bending angle precision: 30

Temperature and Humidity Operation: 10°C - 28°C / 5% - 95% without water condensation

Motor capacity: 9KW to 11KW Siemens

Lower table: Robust, ideal for quick matrix changes

Bender structure: Steel made with tension relief welded

Pedal: Included high precision

Dimensions: 128" x 63" x 81"

Weight: 14,000 pounds (MAKE-10-NC125T) and 18,500 pounds (MAKE-10-NC200T)

Voltage / Hertz: 220V/60 GHz 3-PHASE

Warranty: 1 year for mechanical and electronic parts

WARRANTY

In FlexMax Laser & CNC Machines we exceed our compromise with our customers. Our most important goal is to full fill your expectations and needs.

We provide outstanding customer service to satisfy our customer request.

FLEXMAX LASER & CNC MACHINES ALSO OFFERS:

- COMPLETE INVENTORY OF SPARE PARTS FOR ALL THE LASER ENGRAVER & CUTTER MODELS.

- SPECIALIZED TECHNICAL SUPPORT.

- FAST RESPONSE TO OUR CUSTOMER REQUIREMENTS

- CONTINUOUS IMPROVEMENTS IN OUR SERVICE.

FlexMax Laser & CNC Machines offers a comprehensive warranty policy, for more information and complete terms: CLICK HERE