Flex Laser

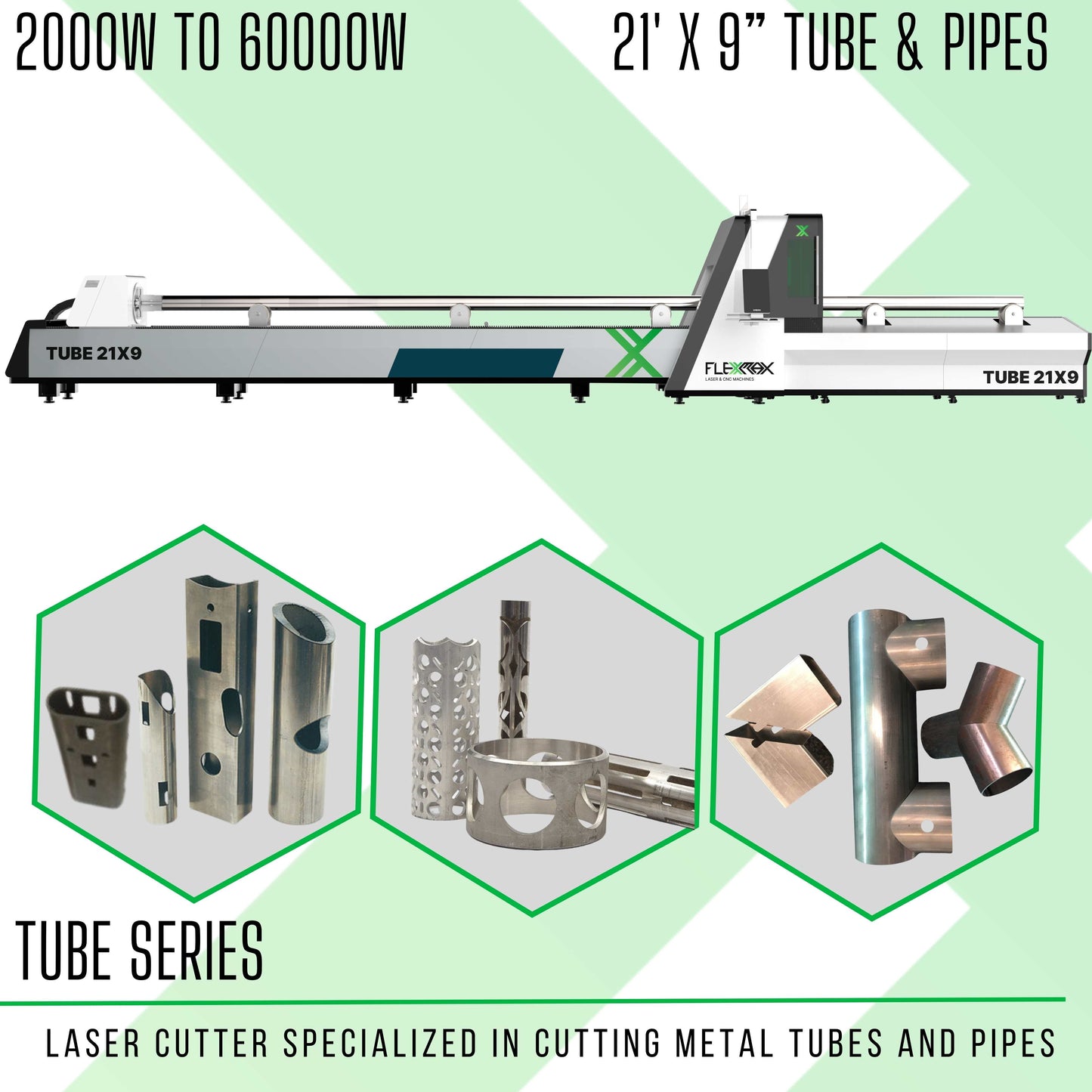

2000W to 6000W tubes cutter FlexMax Fiber Laser TUBE Series for 20' long metal tubes & pipes

2000W to 6000W tubes cutter FlexMax Fiber Laser TUBE Series for 20' long metal tubes & pipes

SALE METHOD: FROM THE FACTORY TO YOUR FACTORY WITH LOCAL TRAINING AND SUPPORT

Our TUBE Series Cutter includes:

✔ FREE Shipping* (Forklift or tow truck crane is required)

✔ 5-DAY Full Pack On-site Installation and training

✔ 2000W, 3000W, or 6000W Fiber Laser Source

✔ Cutting Area: 20' length x 8" diameter (tubes and pipes)

✔ Hydraulic material receiver and tube holder

✔ CypCut T Professional Cutting Software

✔ Servo Movement System

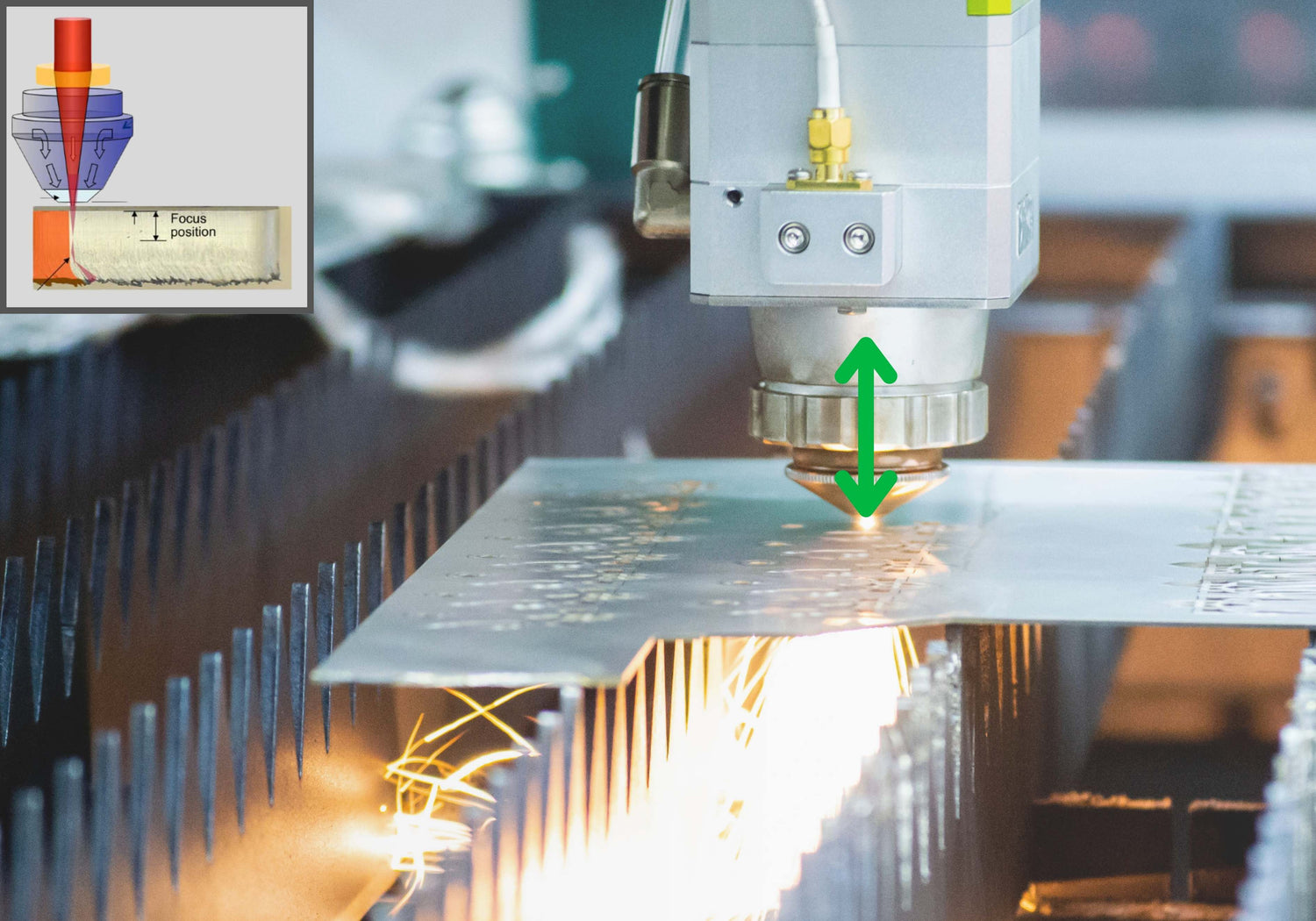

✔ Raytools Dynamic Autofocus Laser Head

✔ Industrial Electrónic Chiller

✔ Automatic Lubrication System

✔ PC with Pre-Installed System

Couldn't load pickup availability

Share

INTRODUCTION

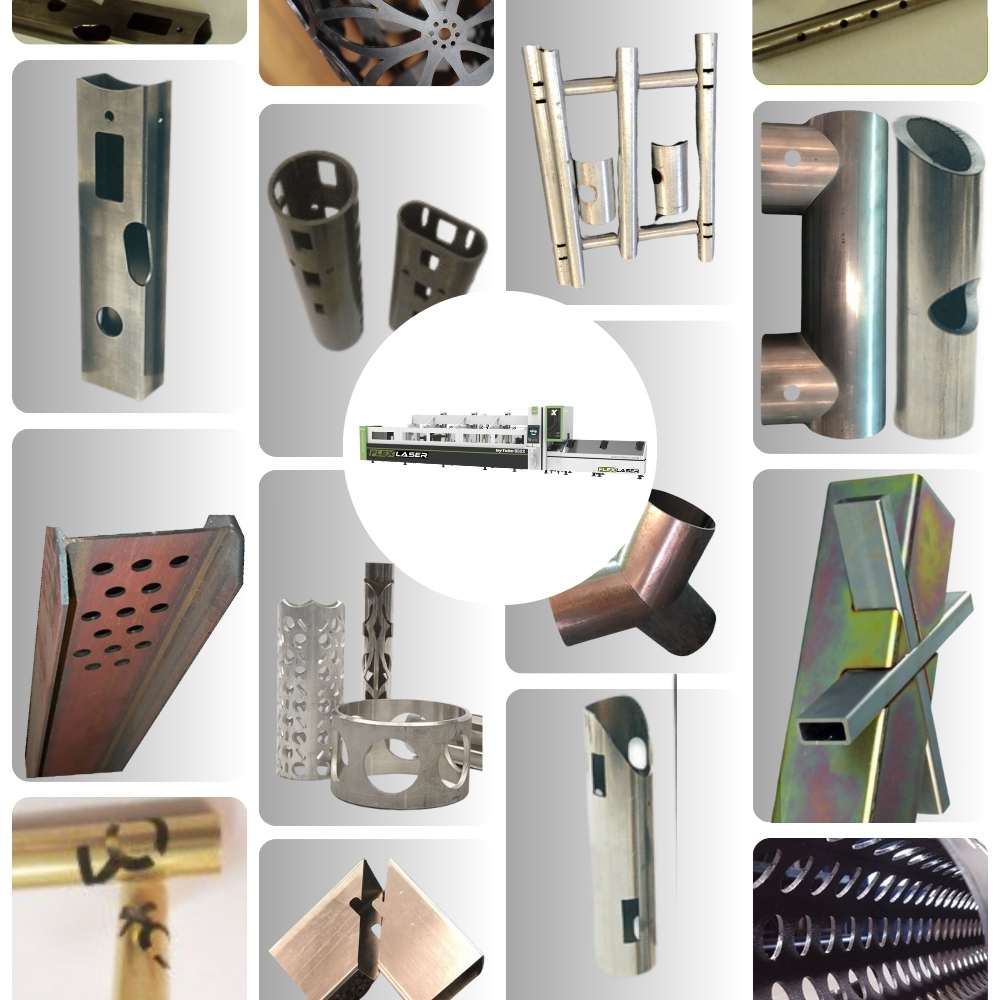

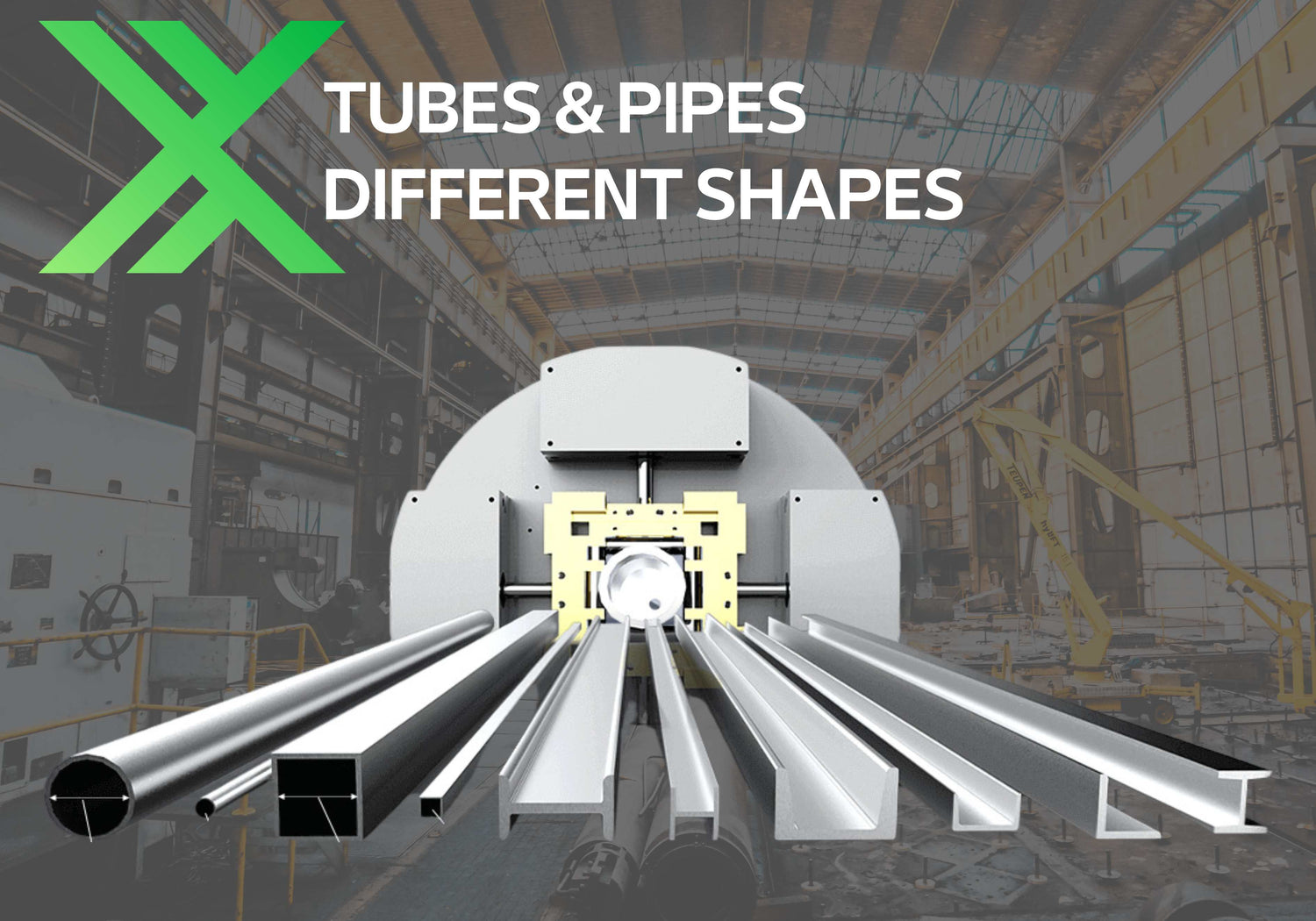

Our TUBE Series is a specialized tube and pipe laser cutter, the best tool for cutting different shapes and thicknesses of stainless steel, galvanized steel, aluminum, and mild steel tubes with high precision and speed.

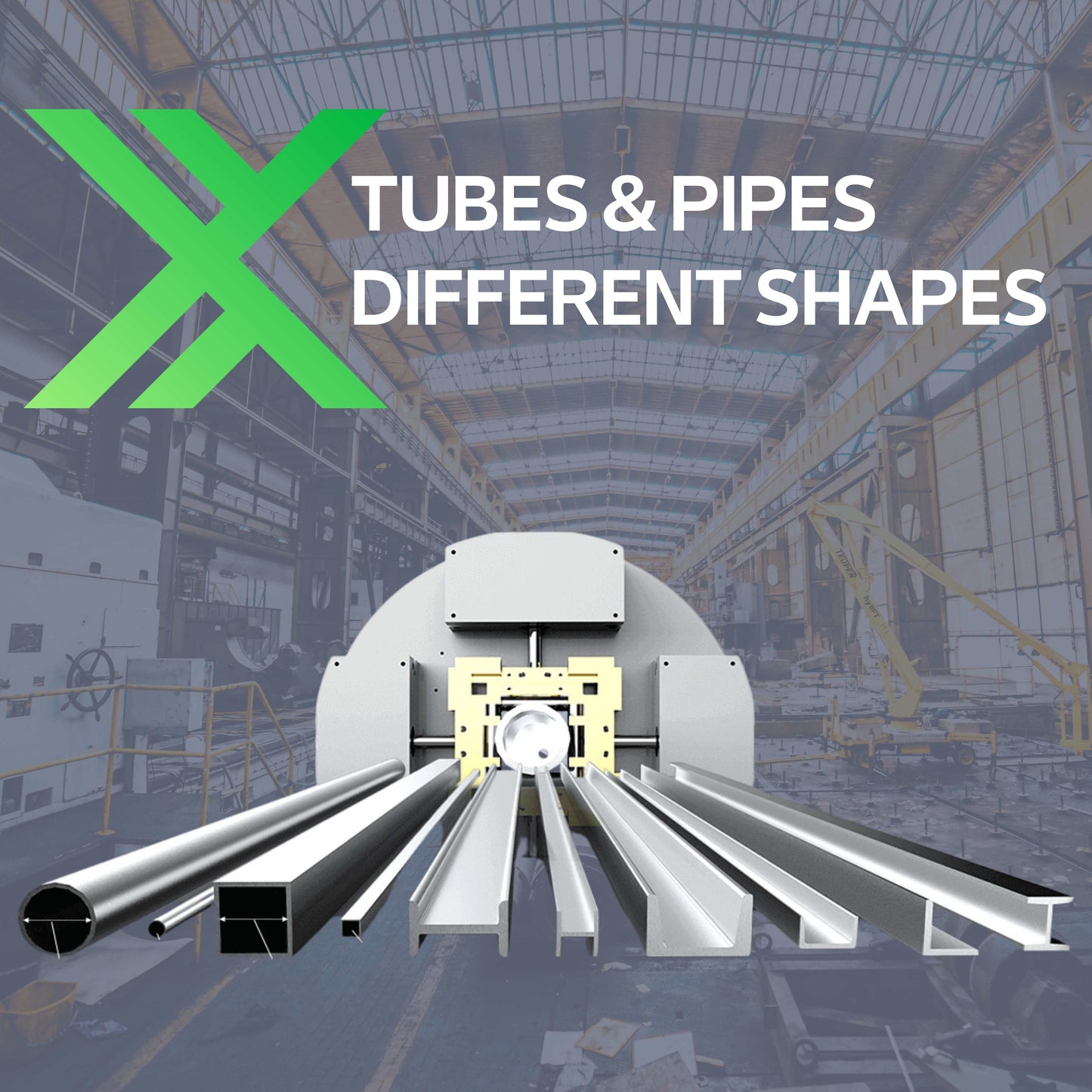

DIFFERENT SHAPES

The tubes series can cut different shapes and thicknesses of tubes and pipe metals, such as square, round, rectangle, H beam, and C beam, among other types.

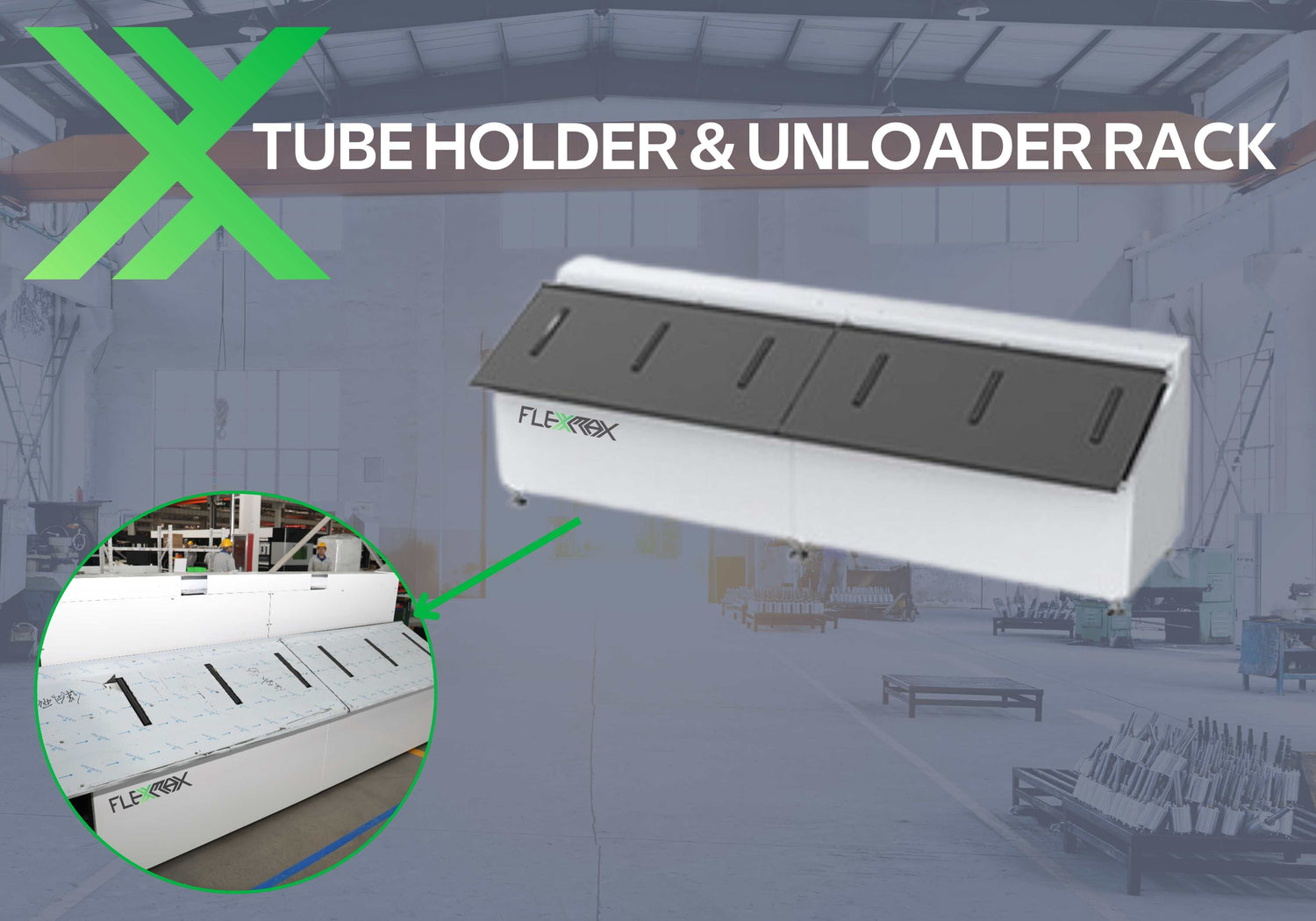

RECEIVING HOLDER

This electronic-hydraulic device has two functions: first, it supports the excedent of the tubes while the machine is cutting, and second, it receives the pieces and allows them to drop smoothly.

HIGH SPEED CHUCK

The TUBE Series features a higher-efficiency chuck with a maximum speed of 150 rpm, resulting in increased profitability.

WHAT CAN I CUT?

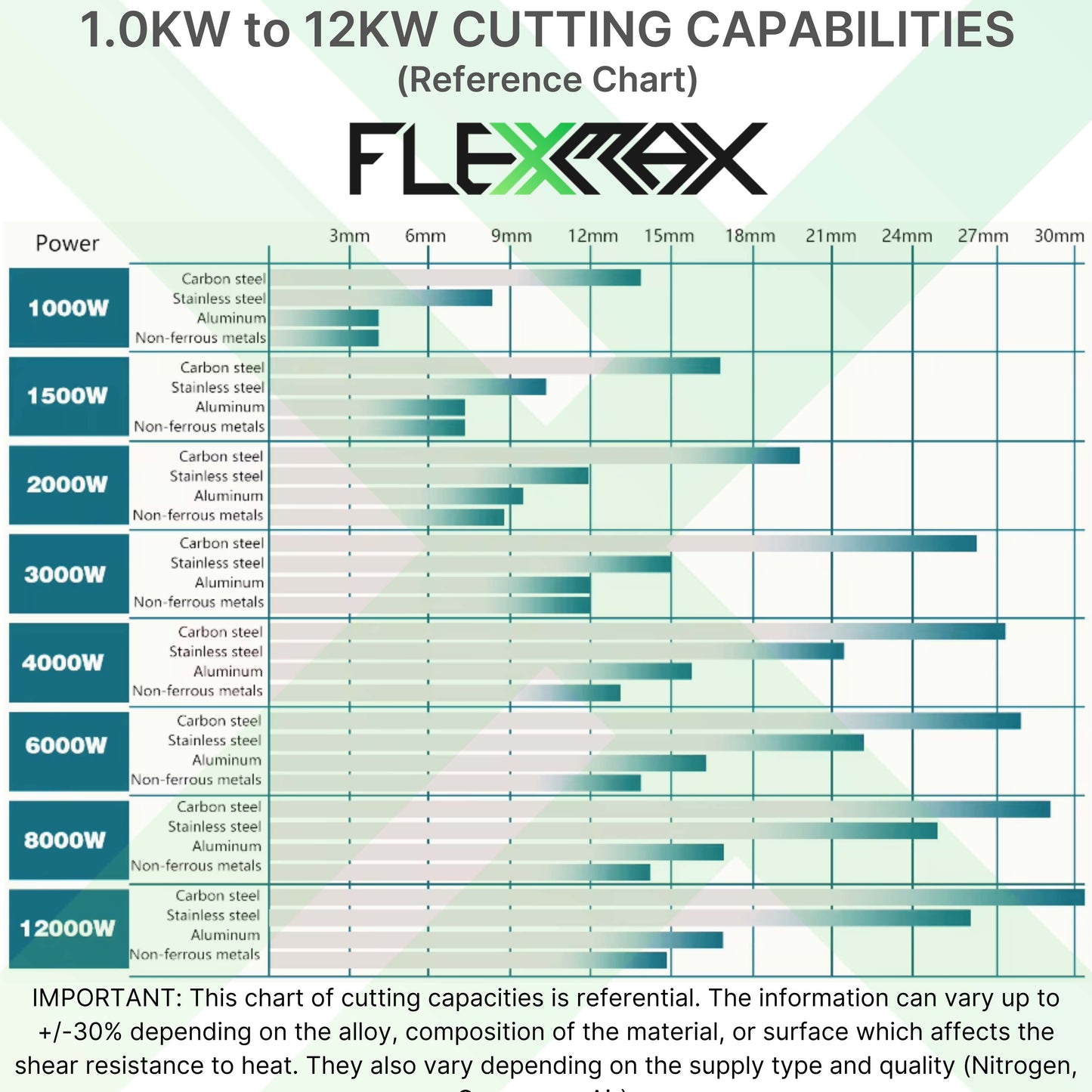

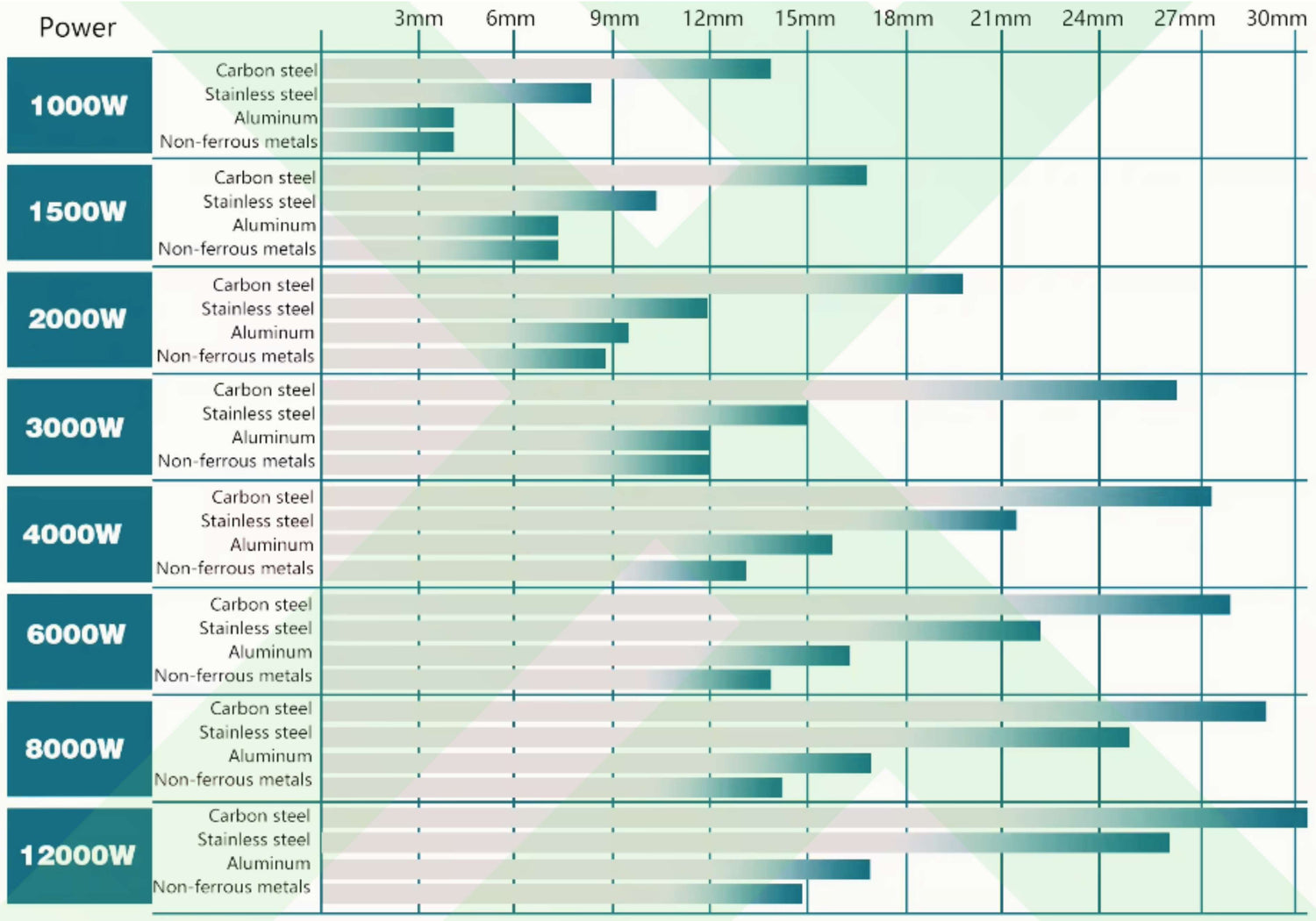

Our NOVA Series can cut stainless steel, carbon steel, mild steel, Galvanized steel, and aluminum. This chart is referential and can vary by up to +/-30% depending on the alloy, material composition, surface, supply type, and quality (Nitrogen, Oxygen, or Air).

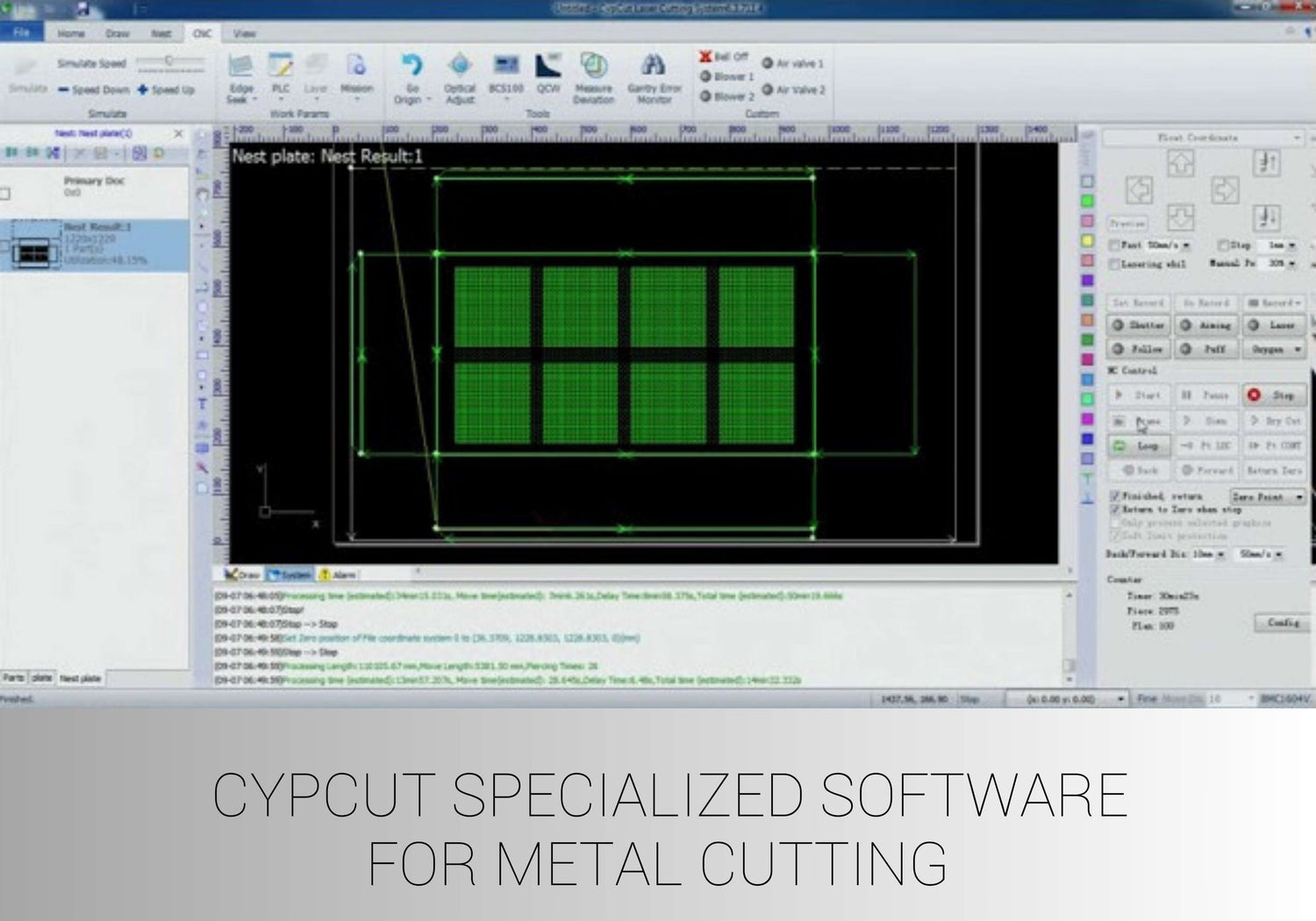

CYPCUT T SOFTWARE

CypCut is the world's most popular cutting software for abundant online support material. This system offers total and efficient machine control and allows processing files DXF, PLT, and AI LXD.

LASER SOURCE

Our fiber metal cutters are equipped with Max Photonics laser generators, TOP BRAND specializes in manufacturing fiber optic metal cutting sources.

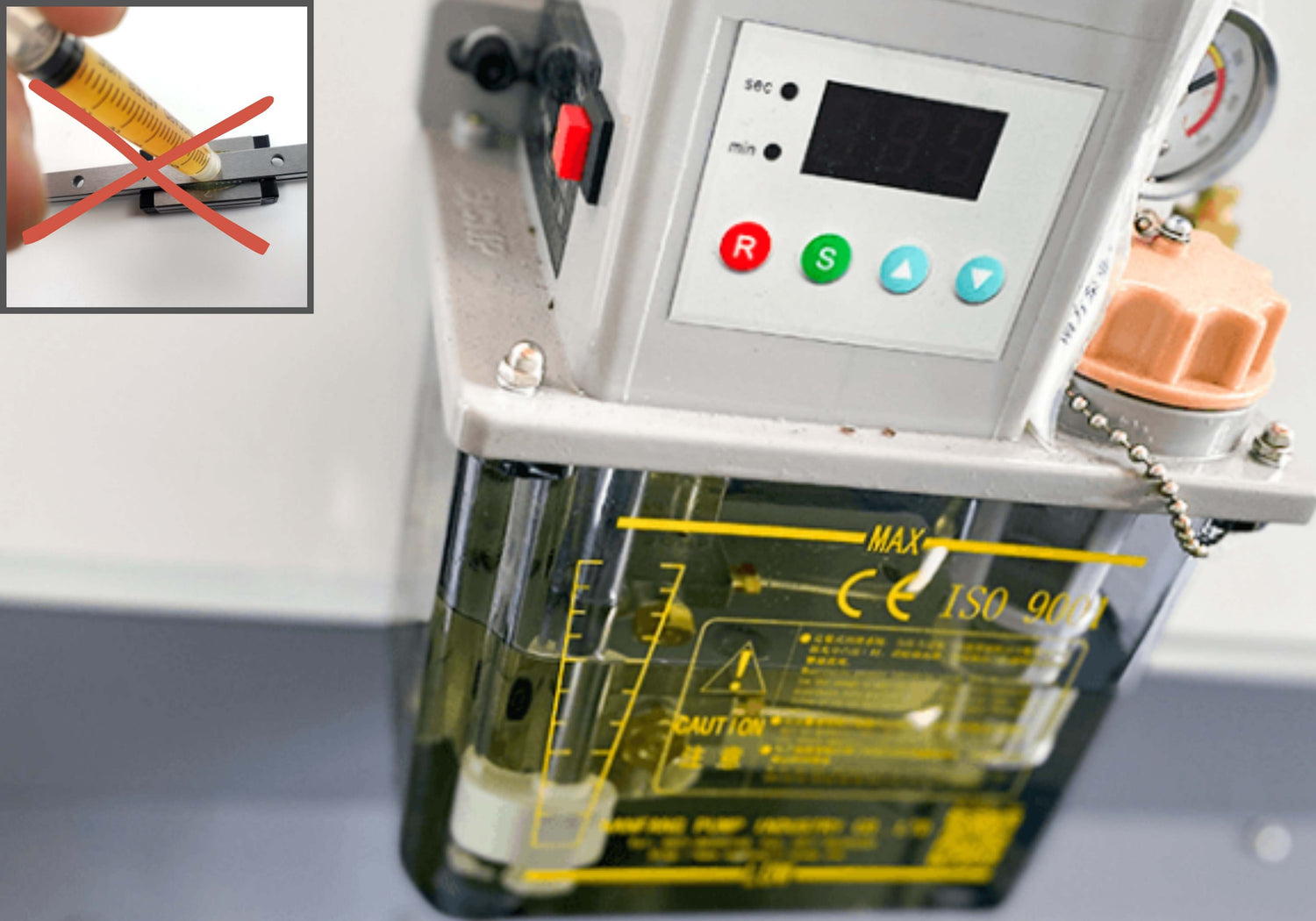

AUTOMATIC LUBRICATION

Lubrication and maintenance are basic needs for a laser cutter, so we equip them with automatic lubrication systems, which have a technique that transfers oil to sensitive places.

DSP EASY CONTROL

FlexMax Laser includes an industrial-grade DSP hand controller to operate the metal cutter efficiently from a safe distance.

AUTOFOCUS HEAD

Metal sheets are never entirely flat; they have waves or are uneven. The “Auto Focus” is an efficient height regulation system with a height sensor equipped in the cutting head; it detects the distance from the output nozzle of the laser light beam to the material's surface.

INDUSTRIAL COOLING SYSTEM

This includes an “industrial” water cooling and refrigeration system; the chiller is electronically controlled, keeping the water cold. Just adjust the temperature required by the system.

FACTORY TO FACTORY

We ship the machine directly from the factory to your location anywhere in the USA. Once it arrives, an engineer will install it and train you to use it with your materials and projects. ALL-INCLUSIVE!

2000W to 6000W tubes cutter FlexMax Fiber Laser TUBE Series for 20' long metal tubes & pipes

Collapsible content

TECHNICAL SPECIFICATIONS

TECHNICAL SPECIFICATIONS - TUBE Series

Laser Generator Power: 2000W, 3000W, or 6000W.

Laser Source Brand: MAX Photonics.

Machine Weight: 14,300 lbs.

Machine Dimensions: 468 x 63 x 89 inches.

Machine Cutting Area: 21 ft length x 9" diameter

Software: CypCut.

Supported Formats: DXF, PLT, AI, LXD.

Cutting Speed: 14 meters x min depending on the material and thickness (Up to 1.4G).

Chuck Rotary Speed: 150r/min.

Movement System: Full Servo

Transmission type: Rack and Pinion (Taiwan).

Re-positioning Accuracy: ±0.02/1000 (mm).

Velocity of Displacement: 14,000mm/min.

Lubrication System: Automatic.

PC with Pre-installed Software: Yes (Integrated).

A/C System: Integrated for the electronic components zone.

Cooling Method: CWL Refrigerated Electronic Chiller (included).

Operating Temperature: 10°C - 28°C.

Operating Humidity: 5% - 95% without water condensation.

Machine Energy Consumption: 7KW to 11KW, depending on the laser source power.

Voltage/Hertz: 220V/60Ghz 3P.

Warranty: 3-YEAR for 6000W generators, 2-YEAR for 4000W and 3000W generators, 1-YEAR for electronic and mechanical components, and six months for labor (The warranty does not include consumables or travel expenses).

WARRANTY

In FlexMax Laser & CNC Machines we exceed our compromise with our customers. Our most important goal is to full fill your expectations and needs.

We provide outstanding customer service to satisfy our customer request.

FLEXMAX LASER & CNC MACHINES ALSO OFFERS:

- COMPLETE INVENTORY OF SPARE PARTS FOR ALL THE LASER ENGRAVER & CUTTER MODELS.

- SPECIALIZED TECHNICAL SUPPORT.

- FAST RESPONSE TO OUR CUSTOMER REQUIREMENTS

- CONTINUOUS IMPROVEMENTS IN OUR SERVICE.

FlexMax Laser & CNC Machines offers a comprehensive warranty policy, for more information and complete terms: CLICK HERE